Stainless Steel SS Coalescer Filter Cartridges, Rs 5500 /unit(s) ID

A coalescing filter is a device that separates certain liquid and gas particulates from liquid and gas media. Coalescer filter media comprises multiple material layers, which differ depending on filtration requirements. These materials bond to form a single filter media. Coalescer filters generally follow these standard steps:

Coalescers and Coalescer Filter Systems Coalescer Filter Separator

Part Number and Ordering Information. Pall 6" diameter coalescer retrofits are available to replace the following suppliers products. Please contact your Pall representative if your don't find the 6" Liquid/liquid coalescer reference you use listed below: Recommended change-out: 1.0 bard / 15 psid at. 21 °C / 70 °F.

6” Diameter Coalescer Retrofit Filter Elements and Separator

Coalescing filtration is a process that is widely used in industrial settings to remove oil, water, and particles from compressed air systems. Coalescing filters work by trapping and eliminating submicron-sized liquid oil, water droplets, and solid particulate matter. These filters are essential in maintaining the quality of compressed air.

Mild Steel 28Kg/cm2 Coalescer Filter (Imported), For Ammonia

a coalescing filter, knock-out drum or a mist eliminator vessel to remove particulate matter and entrained liquids; 3. a guard bed using an adsorbent such as activated carbon to remove the heaviest hydrocarbon fractions, including compressor oil; 4. a downstream particle filter to capture any fines from the guard bed; 5.

How Does a Coalescer Filter Work? Hollingsworth & Vose

A coalescing filter or coalescer is an industrial device that separates fluid mixtures into individual components. Industrial process fluids contain various impurities like sulfur, ethane, carbon dioxide (CO 2 ), water vapor, methane, etc. To maintain the quality of the final product, these impurities must be removed from the mixture.

Gas Filter & Coalescing Elements Pumping & Filtration Solutions

Coalescing performance is determined by the type and number of layers of fiberglass. Royal Coalescers are available in four different series of efficiency. fuels such as diesel or heating oils. place of the 25 series when more efficiency is or tighter filtration is desired. lighter hydrocarbons such as kerosene, gasoline, or naphtha.

Fiberglass Coalescer Filter, Rs 1200 /piece Environmental Engineering

Borosilicate glass microfibers are considered to be the ideal filter media available for the coalescing of liquid aerosols. This material is neither liquid adsorbent nor absorbent and consequently, is superior for retaining its original properties while in service. The C-Type element has a two-layer structure, an inner particle capture-layer and an outer drainage layer. Liquid […]

GR Series Wet Gas Coalescer FLTR

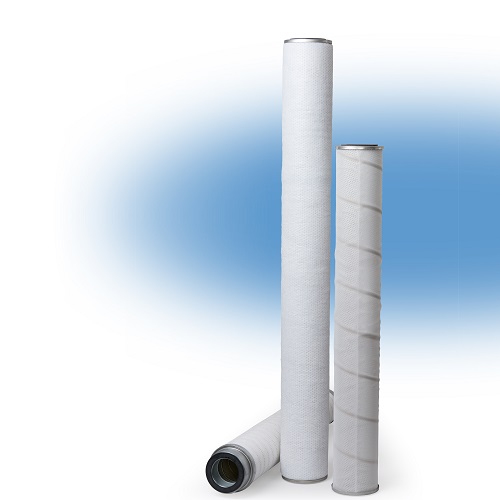

Gas-Liquid Coalescer Filters: Standard Length - 36″ and 40". Standard Diameters - 2.75″, 4.5" and 6″. Many Other options are available, consult factory. Material Choices. Liquid-Liquid Coalescer Filters: Coalescing Media - Fluoropolymer, Polyester, Polyolefins, Nylon. Support Layers - Cellulose, Polyester, Polypropylene, Nylon.

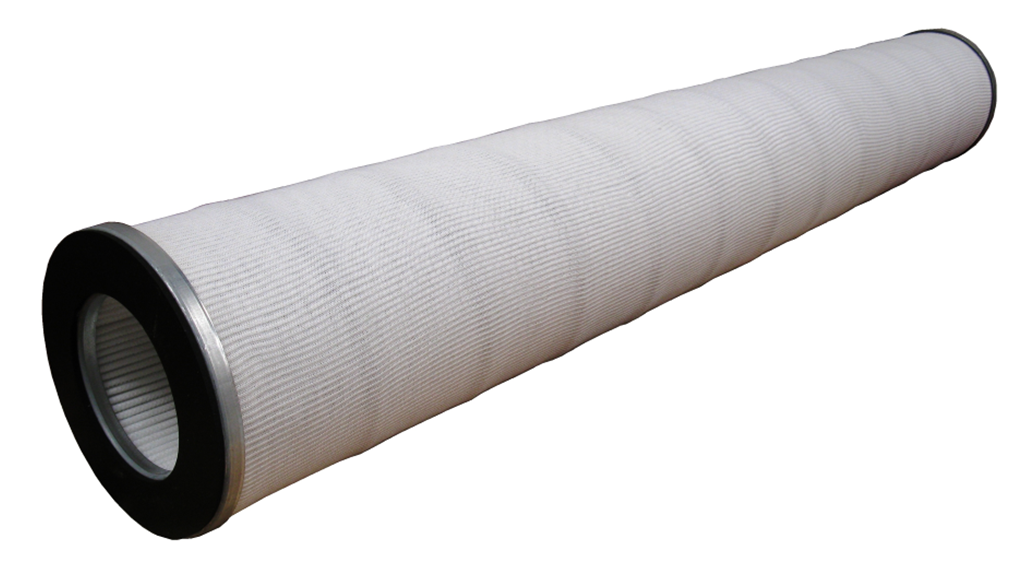

High Flow Coalescer Filter Element Manufacturers Buy HUAHANG

Filson air coalescing filter element is used to remove oil, water and liquid contaminations from natural gas or compressed air system. It offers coalescing grades with 95% to 99.99% efficiency. Filson has replacement Peco coalescer elements and Parker coalescing filter element in stock. Send Inquiry. Filson Coalescer Elements For Coalesce Skid.

Cylindrical Coalescers Begg Cousland Products

Hollingsworth & Vose Company 112 Washington Street East Walpole, MA 02032 U.S.A. 508-850-2000. Heavy basis weight. Corrugation. MFP of 30+ microns. Acrylic, phenolic, or blended binder types. High strength. Low levels of glass fibers. Hollingsworth & Vose Europe Friedberger Strasse 191. D-61118 Bad Vilbel, Germany.

What is coalescing filter and how does it work? Brother Filtration

Each coalescer filter material is tailored to the particular needs of the application, with a variety of filtration grades for different coalescer functions and media. When used for liquid/liquid separation, coalescer filters remove water from various petroleum-based liquids such as jet fuel, diesel, and hydraulic fluid.

Coalescer filter elementen Interfilter

The main work of this Coalescer Filter Separator is to remove unwanted materials from the useable substances. So, these unwanted materials or contaminants pre-exist in the substance before going through Coalescer Filter Separator.. A filter separator will remove various types of contaminants, including the oil and water contaminants present in the pre-treated gas and liquid.

Micro Glass Fiber Coalescer Filter Element JPMG 336CER High Efficiency

Before GC/MS analysis procedures, the extracts from filter, PUF, and XAD-2 resin were combined. So, ambient BaP concentrations in this paper were the sum of aerosol and gas phase BaP concentrations.

6.4MPa Pressure Coalescer Filter Element With Wool Felt Gasket

Each coalescer filter material has a range of filtering grades for various coalescer functions and media and is specifically designed to meet the requirements of the application. Coalescer filters are used to separate different petroleum-based liquids, such as hydraulic fluid, jet fuel, and diesel, by removing water..

New coalescer for oil and gas processing Engineer Live

Therefore, chemical compatibility and hydrophilic or hydrophobic properties of filter material must be taken into fully consideration. Coalescer separation filter is mainly used in liquid-liquid separation and gas-liquid separation applications, aiming to filter out trace droplets (water or oil) and solid particles from gases, or remove another.

What is a coalescing filter?

The Coalescer filter has been specially designed to separate water from hydraulic fluids. According to VDMA standard sheet 24568, the amount of water in. DIN ISO 2943 Hydraulic fluid power filter elements; verification of material compatibility with fluids DIN ISO 3723 Hydraulic fluid power filter elements; method for end load test